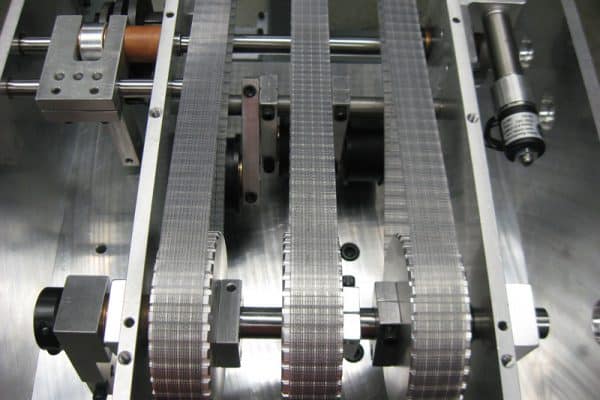

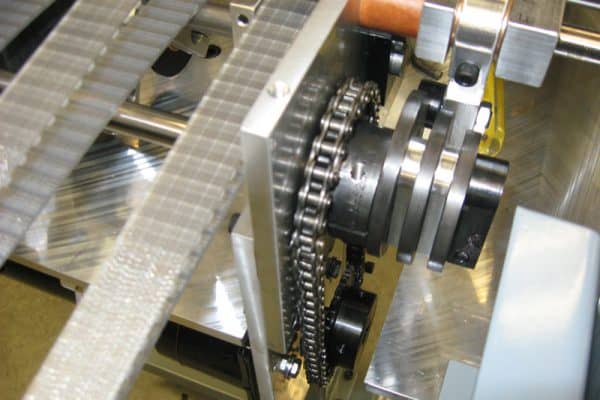

A CD/DVD manufacturer needed an automated machine to feed cases onto a conveyor for further processing. At the time, there were two workers on the line: one to open cartons and place individual cases on a table; the other to manually feed the cases onto the conveyor.

ETI designed a feeder that consolidated the two jobs into one. Now, the product passes through the process line, and when necessary, augments the normal flow of product for improved throughput. The PLC controlled logic system also monitors the downstream backlog and will disengage the feeding mechanism when needed.

Project

Model 306 Case Feeder

Client

Technicolor

What We Did

Designed a feeder for greater line efficiency and labor cost savings.